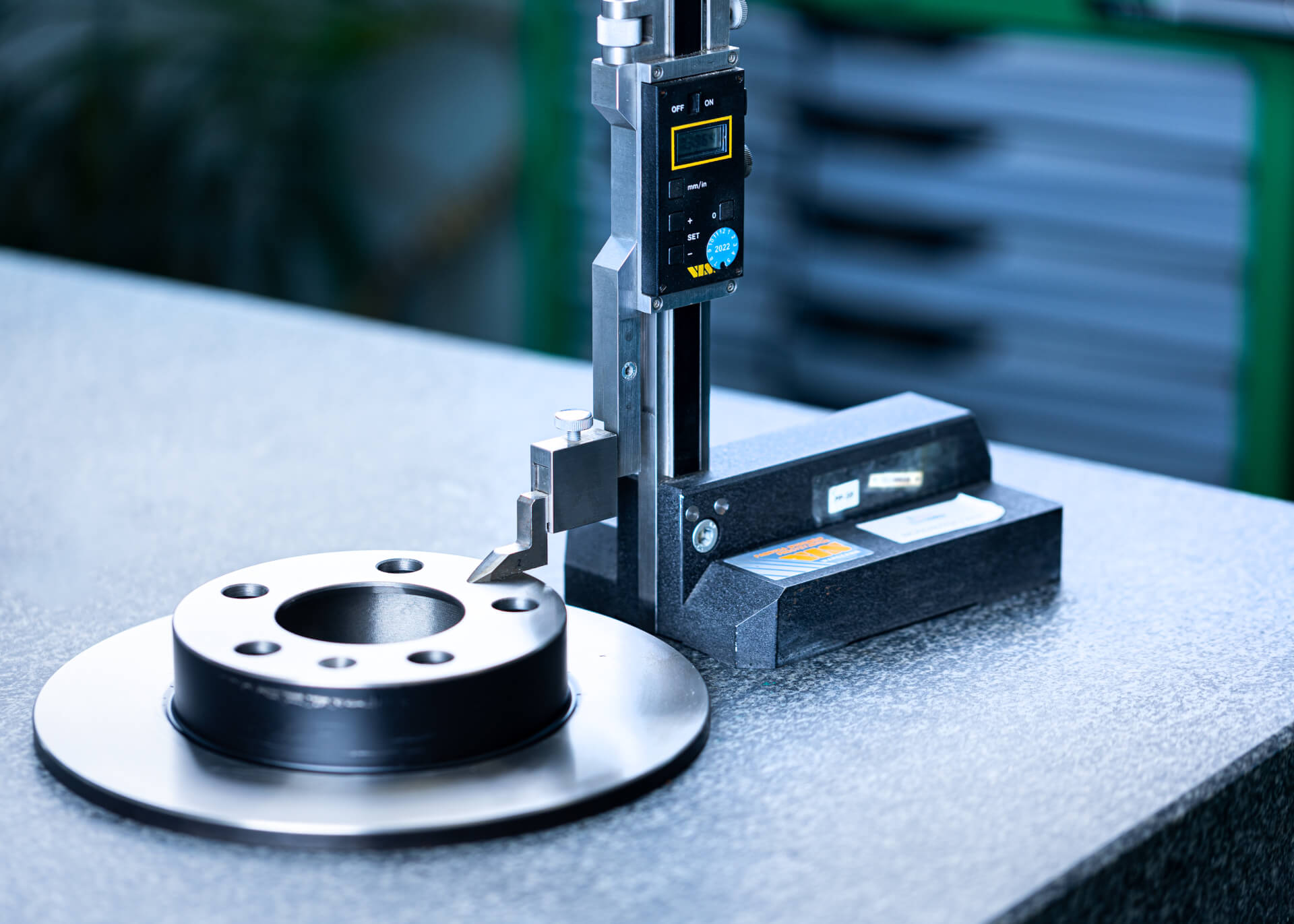

Geometrical parameter testing

The dimensions of the parts must be in line with the technical documentation. The precision, fit and assembly of components such as hubs or bearings, for example, require measuring equipment with high accuracy. Aberration from standard dimensions must stay within very strict geometrical tolerance specified by the constructor.

Hardness and microhardness testing

Hardness testing is a fundamental test of material’s physical properties. Being able to demonstrate that the hardness of a material is in accordance with the specification requirements and documentation provided is becoming increasingly important when dealing with customers and business partners. We provide comprehensive services for measuring the hardness of materials, as well as some coatings or layers. We have the following hardness testers: Rockwell [HRC], Brinell [HB], Vickers [HV] and Vickers microhardness [µHV].

Shore's method hardness testing of rubber

The hardness of polymeric materials is determined using the Shore method according to standard PN-ISO 868, with an indenter according to standard PN-93/C-04206.

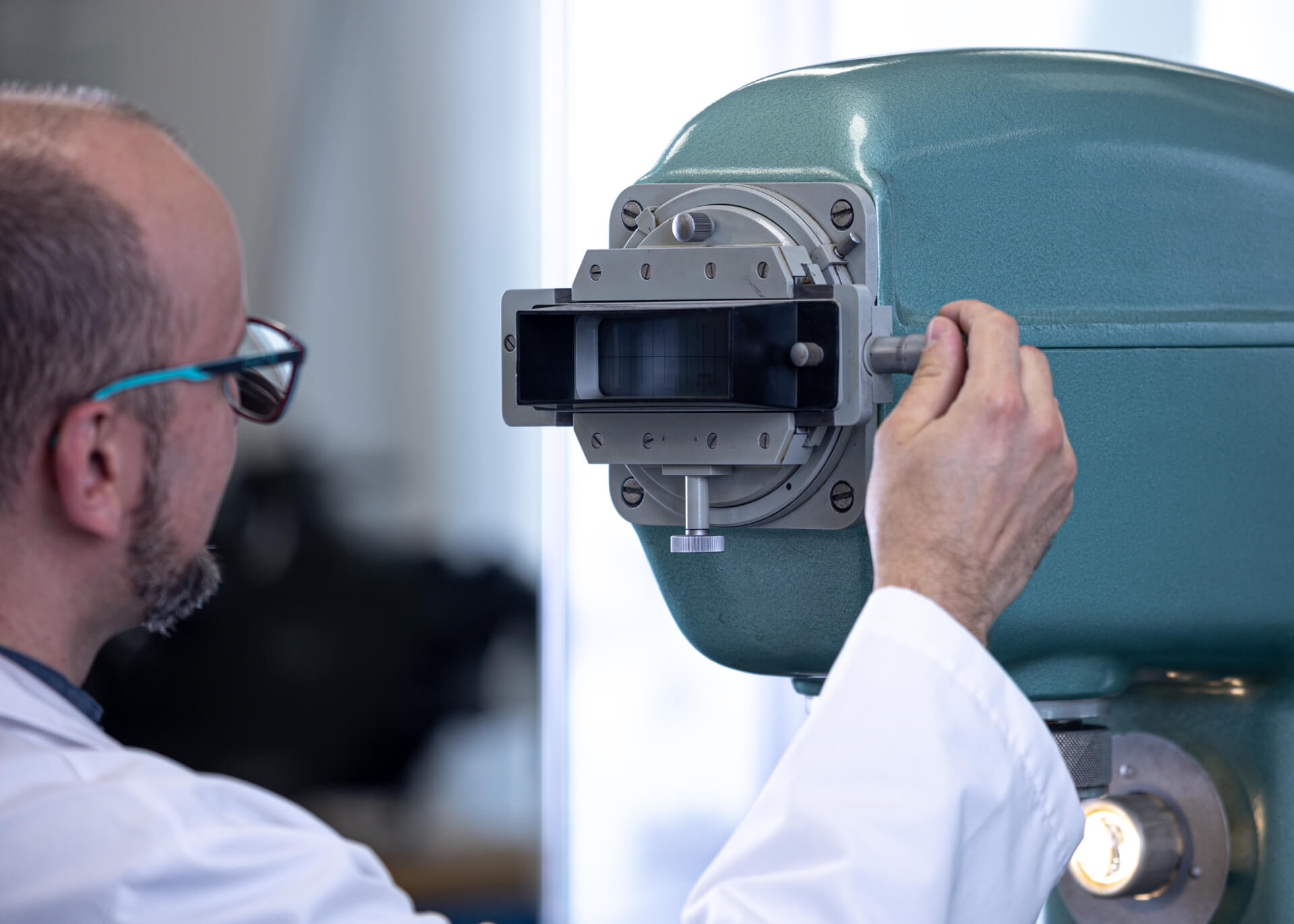

Metallographic tests

Metallographic testing involves the observation of natural surfaces or specially prepared metallographic samples to determine the structure, assess quality or identify discontinuities in tested material.

XRF chemical composition analysis

We have the latest generation of portable XRF (X-ray fluorescence) spectrometer from Olympus. The spectrometer makes it possible to analyse the chemical composition of steel and other alloyed metals using a non-destructive method. In addition, we are able to check the presence of harmful elements in accordance with the RoHS directive in a variety of materials. Detection in units of [ppm].

Roughness tests

Roughness measurements are carried out using a special device – a profilometer. Asperity/roughness is one of the important characteristics of metal surface, especially when the components under examination have previously undergone mechanical or thermal treatment.

Tensile strength tests

The testing machine – a hydraulic tensile test machine – enables physical characteristics to be obtained for metallic, composite and other materials. Our laboratory tests strength parameters, such as: Young’s modulus, tensile strength, yield strength and elongation at break. We have a German machine made by Heckert, with a measuring range of 40 kN, along with equipment for tensile, compression and bending tests.

Dynamic (fatigue) tests

A testing machine with a range up to 10 kN allows static tests for tension, compression and bending.

Corrosion resistance tests

The test is carried out in line with PN-EN ISO 9227 norm in neutral salt spray (NSS) to evaluate the corrosion resistance of metallic materials with or without permanent or temporary corrosion protection.

Functional testing of suspension shock absorbers

On a special bench we are testing, how the shock absorbers work. In order to do this, we need to force the moves of piston rod and register the damping force which is measured on bound and rebound of the absorber.

Tightness testing

Tightness testing is carried out on components such as radiator heat exchangers used to cool internal combustion engines, expansion tanks, radiators, brake lines. These tests allow us to quickly detect gasket damage or product incompatibility.

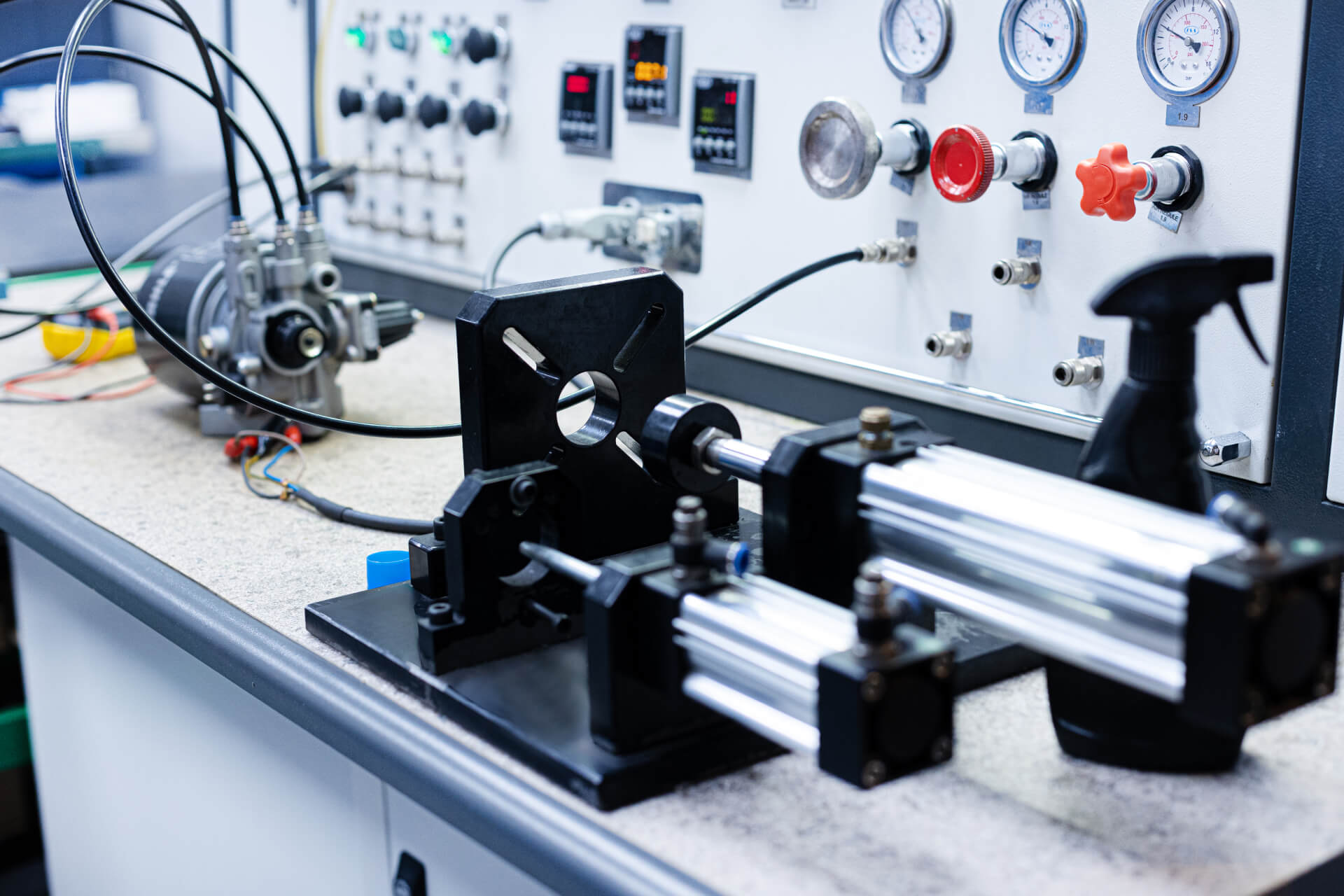

Functional tests of truck brake valves

Intermeko Europe has been equipped with a complete test unit to check the air valves operating in the braking systems of trucks.

Compressors - functional and performance tests

Automotive air-conditioning compressors diagnostic station. The tester is used to check the condition of vehicle air conditioning compressors operating with R134a or R1234yf refrigerant.

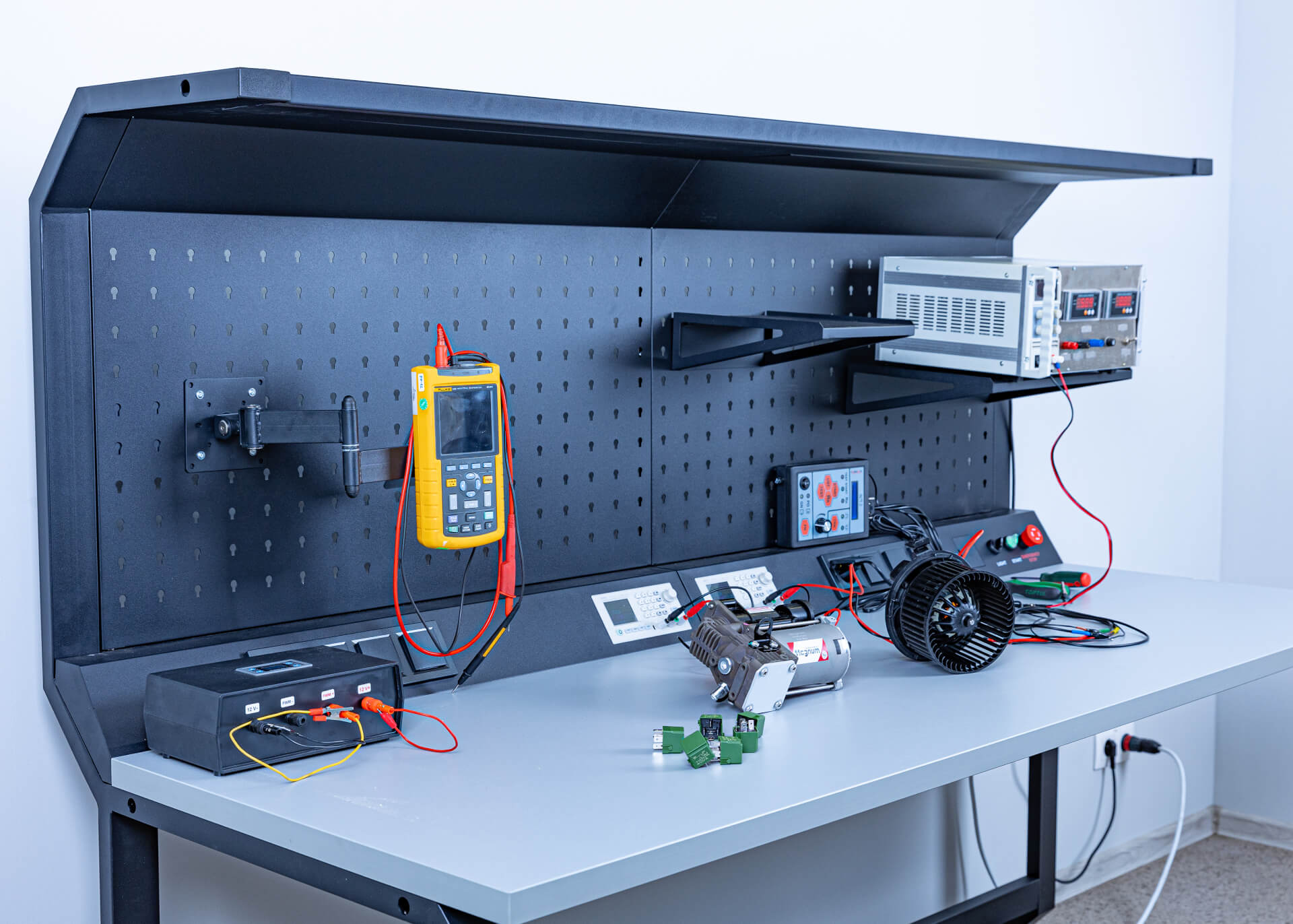

Electrical testing

Test bench for verifying the basic functional parameters of electrical equipment, including window regulator motors, wiper motors, blower motors and many others.